ABA layers film blowing machine,with two extruders produce ABA layers film.

Our ABA Layers Blown Film Extrusion system delivers energy-efficient and cost-effective production solutions, offering versatility across various applications. In our ABA three-layer co-extrusion blown film machines, dual motors are employed for the extrusion of three layers: one motor serves the inner and outer coating layers, while the second motor manages the inner filling layer. innner layer use recycle material or filling material,to lower cost.This configuration minimizes the requirements for the main machinery, reduces costs, and lowers energy consumption, thereby enhancing the performance of our plastic film blowing machine.

The ABA Layers Blown Film Extrusion presents unique advantages, facilitating the manufacturing of both HDPE and LDPE film while improving film strength through multi-layer co-extrusion. By using a single main extruder for both the inner and outer layers, the need for an additional extruder is eliminated, thereby promoting energy efficiency and decreasing consumption. These features position it as an ideal option for integration with our state-of-the-art plastic film blowing machine.

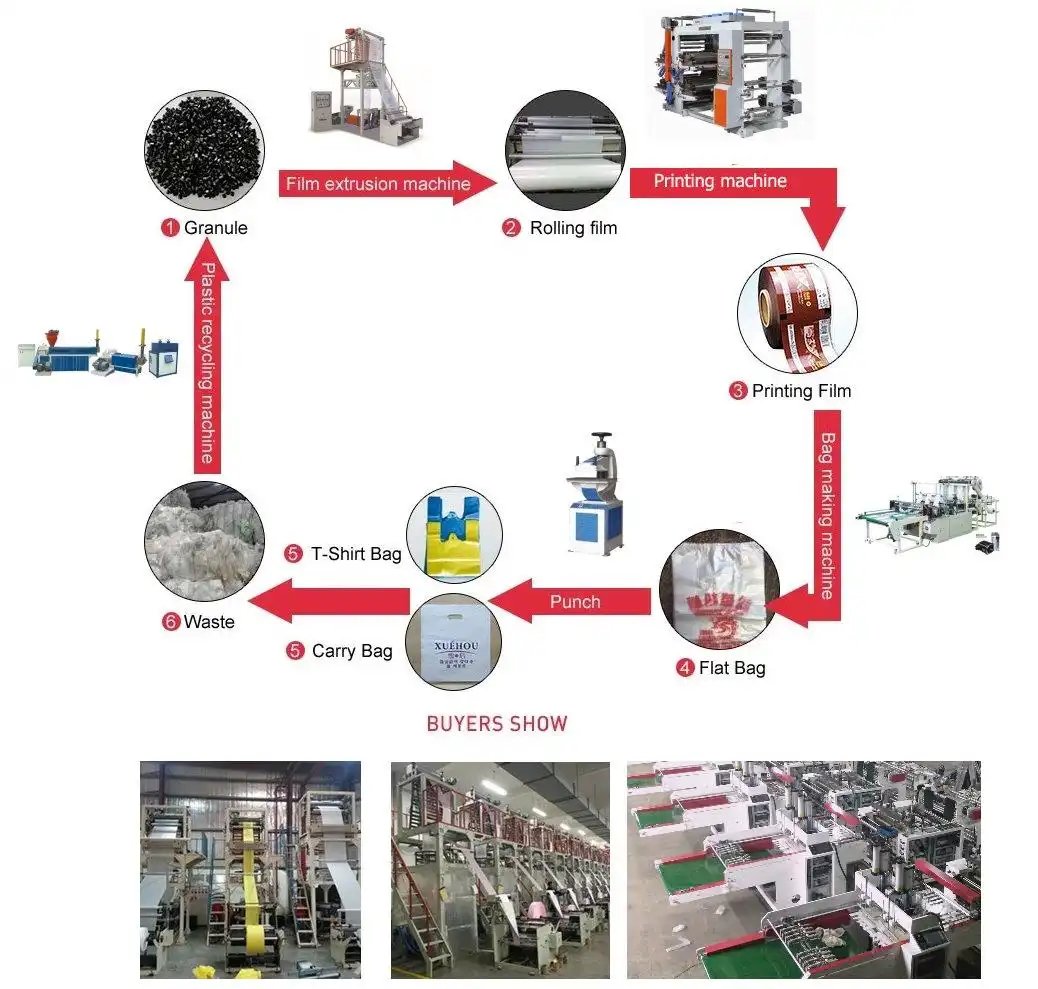

ABA Layers Blown Film Extrusion produce plastic film roller,suit to produce plastic Garbage bag,plastic rolling bag,plastic shopping bag,plastic T-shirt bag,fruit bag,carry bag.

ABA Layers Blown Film Extrusion

ABA Layers Blown Film Extrusion

plastic T-shirt Bag

Optional Device:

1)Auto Loader

2)Air Compressor

3)Rotary Die Head

4)Double Side Winder(Back to back winder)

5)Up and Down

6)Embossing Cylinder

7)Air Shaft

8)Masterbatch Dosing device

9)Automatic Winder Changer

10) Corona treatment

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;