Slitting Machine with side arm crosswise unload roll, suit to slit BOPP film,LDPE film,HDPE film,PP film,PET film,PVC film.

Slitting Machine with side arm crosswise unload roll

The slitting machine, equipped with a side arm for crosswise roll unloading, is ideally designed for the cutting and rewinding of various roll materials such as BOPP, PET, CPP, CPE, PVC, aluminum foil, and paper. It offers functionalities such as edge trimming, material separation, and cutting tailored to specific production needs. Additionally, this slitter machine features edge position control and an automatic tension controller, enhancing operational efficiency.

BOPP film paper

The slitting machine features a side arm that facilitates the unloading of rolls in a horizontal orientation. It is suitable for a diverse range of films such as LDPE, HDPE, LLDPE, BOPP, PP, PET, and paper. This machine incorporates inverter control to optimize slitting speed, thereby promoting energy efficiency and cost reduction. It accommodates films with widths ranging from 100mm to 1300mm and is equipped with controls for edge positioning and automatic tension adjustment. A one-year warranty is included to guarantee dependable operation 24/7. With its user-friendly and economical design, this slitter machine is particularly advantageous for less experienced operators. It operates on power systems of 220V, 380V, 440V, or 480V, with customization options available to meet regional needs. Post-sale support encompasses on-site installation and training conducted by skilled engineers. Clients are invited to request slitting machines tailored to their specific requirements or OEM designs.

Main Technical Variables:

|

Type |

KD-F1300LS |

|

Material |

PET, BOPP, PE, printing composite |

|

Max. Slitting Speed |

10-450m/min |

|

Max.Width of Mother |

1300mm |

|

Width of Final Roll |

30-1300mm |

|

Material thickness |

0.012-0.1mm |

|

Max. Dia. of Mother Roll |

Φ700mm |

|

Max. Dia. Of rewinding roll |

Φ500mm |

|

Flatness rate |

≤0.2mm |

|

Host control |

PLC (Siemens brand) |

|

Touch screen controller |

10” |

|

Slitting knife |

Flat blade 6pcs/Round blade 6pcs |

|

Motor |

3PCS Servo motor 4KW |

|

winding shafts |

3” Slipping shaft 2pcs |

|

Scrap edge blower |

Included |

|

Unwinding shaft |

3” air shaft |

|

Powder brake of unwinding |

10kgs |

|

Slitting accuracy |

±0.5mm |

|

EPC accuracy |

±0.5mm |

|

Total power |

13kw |

|

Low voltage electrical appliances |

Schneider brand |

|

Pneumatic components |

AirTAC brand |

|

Bearing |

NSK brand |

|

Voltage |

380V 50HZ 3PH |

|

Weight of Machine |

3300kg |

|

|

|

|

1.Unwinding section |

|

Adopting a special conical top form, it does not damage the inner wall of the tube core and is fixed. 2. The unwinding is with automatic constant tension control mode. 3. The unwinding diameter is automatically detected by the proximity switch at the unwinding drive shaft, no need to input material thickness. The residual unwinding diameter can be set to automatically slow down and stop, making it easier to receive the next roll of material. 4. It has a mechanism for manually adjusting theedge offilm,adjustment range of±20mm. 5. The CCD camera automatic correction system, automatically corrects the thin film by following the edges and lines. |

|

|

2.Winding section |

|

3 . Up&Down Slipping shaft control by servo motor, and the winding tension is based on the current coil diameter,

5. The PLC automatically controls the speed reduction of the winding servo motor, ensuring that the temperature of the slip shaft does not exceed 50 ° C, greatly extending the service life of the slip shaft. 6. The slip pressure and winding motor torque are automatically adjusted simultaneously. |

|

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

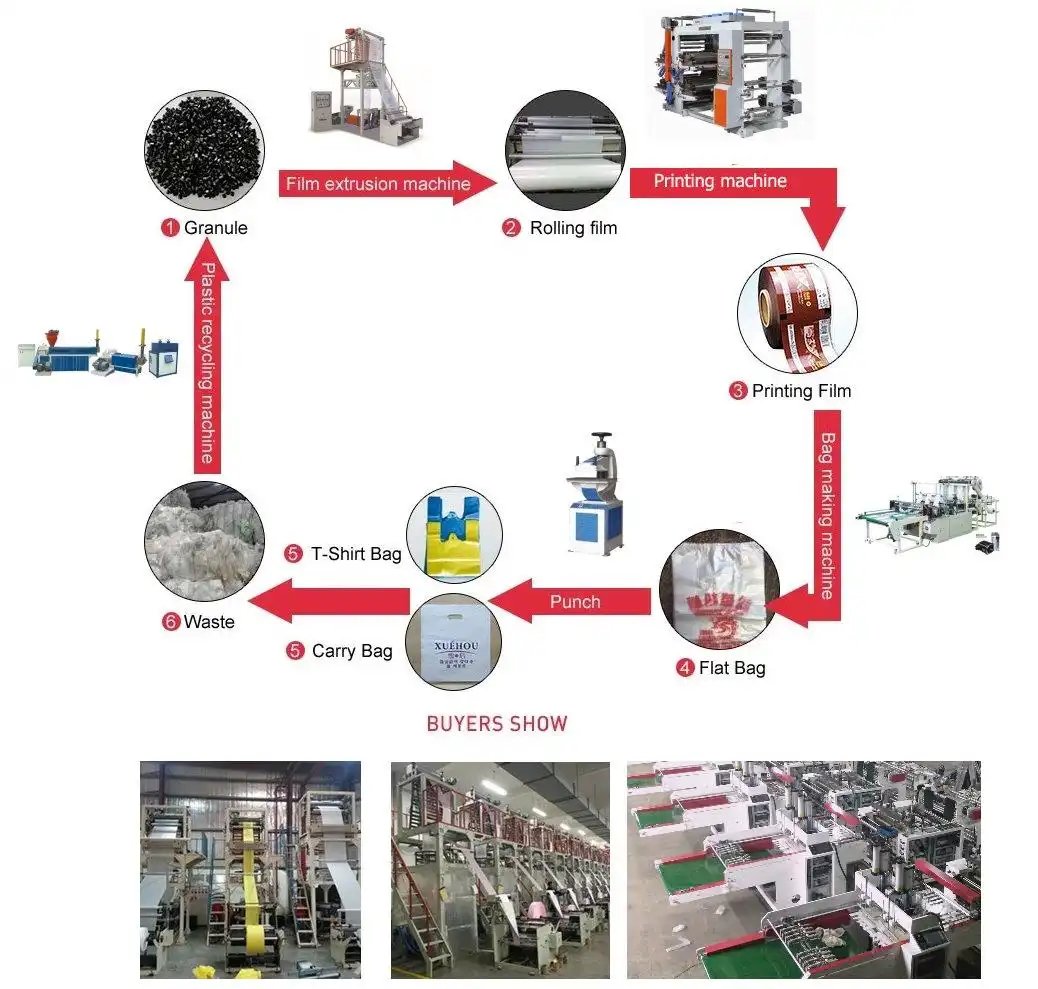

If you only buy one machine,we will pack machine with wooden pack,and loading container withLess Than Container Load(LCL). If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load). Our Main parts cooperator as following brand,but standard parts all made from China. How To Find Polyethelene For Blown Film Extrusion. Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).Shipment

shipment of plastic bag machine

instalment service

install machines in customer factory

Machine parts supplier

Material supplier

Extrusion Film Extrusion use Polyethelene,such as

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;