Optional Equipments:

1)Auto Loader

2)Air Compressor

3)Up and Down

4)Air Shaft

5)Masterbatch Dosing device

6)Automatic Winder Changer

7) Corona treatment

| Model | SJ-B50 | SJ-B55 | SJ-B60 | SJ-B65-1 |

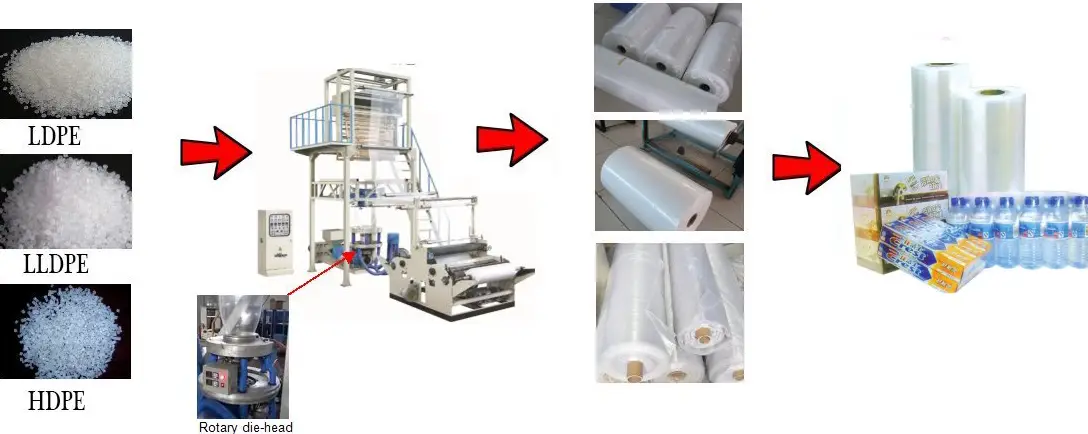

| Material | LLDPE raw material | |||

| Usage | Hot shrink film | |||

| Die-head | Special structure for hot shrink film | |||

| Diameter of screw | φ50 | φ55 | φ60 | φ65 |

| Reduced diameter of film | 100-600 mm | 200-800 mm | 300-1000 mm | 400-1200 mm |

| One side film Thickness | 0.015-0.10 mm | |||

| Max.capacity (Kg/h) | 35 | 50 | 60 | 80 |

| Ratio of Screw L/D | 28:1 | 28:1 | 28:1 | 28:1 |

| Screw material | 38CrMoAl | 38CrMoAl | 38CrMoAl | 38CrMoAl |

| Power of main motor | 11kw | 15kw | 18.5kw | 22kw |

| Power of Traction | 1.1 kw | 1.1 kw | 1.5 kw | 1.5 kw |

| Heating Power | 11kw | 13kw | 19kw | 21kw |

| Machine size | 4.8×1.9×3.8m | 5.5×2.1×4.6m | 6.5×2.3×5.2m | 6.5×2.5×5.2m |

| Weight(T) | 1.5T | 2T | 2.3T | 2.6T |

| Winder structure | Double Side Winder(Back to back winder) | |||

| Power Voltage | 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz…) | |||

| Delivery time | 30-40days | |||

| Material Core Diameter | 76mm(3 inch) | |||

| Machine Working Time | 24 hours * 7 days | |||

| Warranty | 1 year | |||

| Optional Devices | Auto loader, masterbatch dosing system, rotary die head, bubble controller, corona treater, embossing roller, automatic winder | |||

| Technical Assistance | Engineers available to service machinery overseas | |||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.